Inside the Print Farm: A Behind-the-Scenes Look at the 3D2order Studio

In this behind-the-scenes tour you’ll see what really happens inside a working 3D print farm: humming machines, stacks of filament, a sleepy studio dog, a bike trainer in the corner, and the very human process behind every piece that ships from 3D2order.

From the outside, a finished 3D printed piece looks simple: a clean silhouette, smooth curves, the right color. Behind it, there’s a full working space where life and printing overlap—filament spools, late-night tweaks, coffee cups, dog naps, and yes, a bike trainer to keep the human in motion.

This is a peek into the 3D2order studio: not a staged showroom, but the lived-in, fully used print farm where your pieces are designed, tested, and sent out into the world.

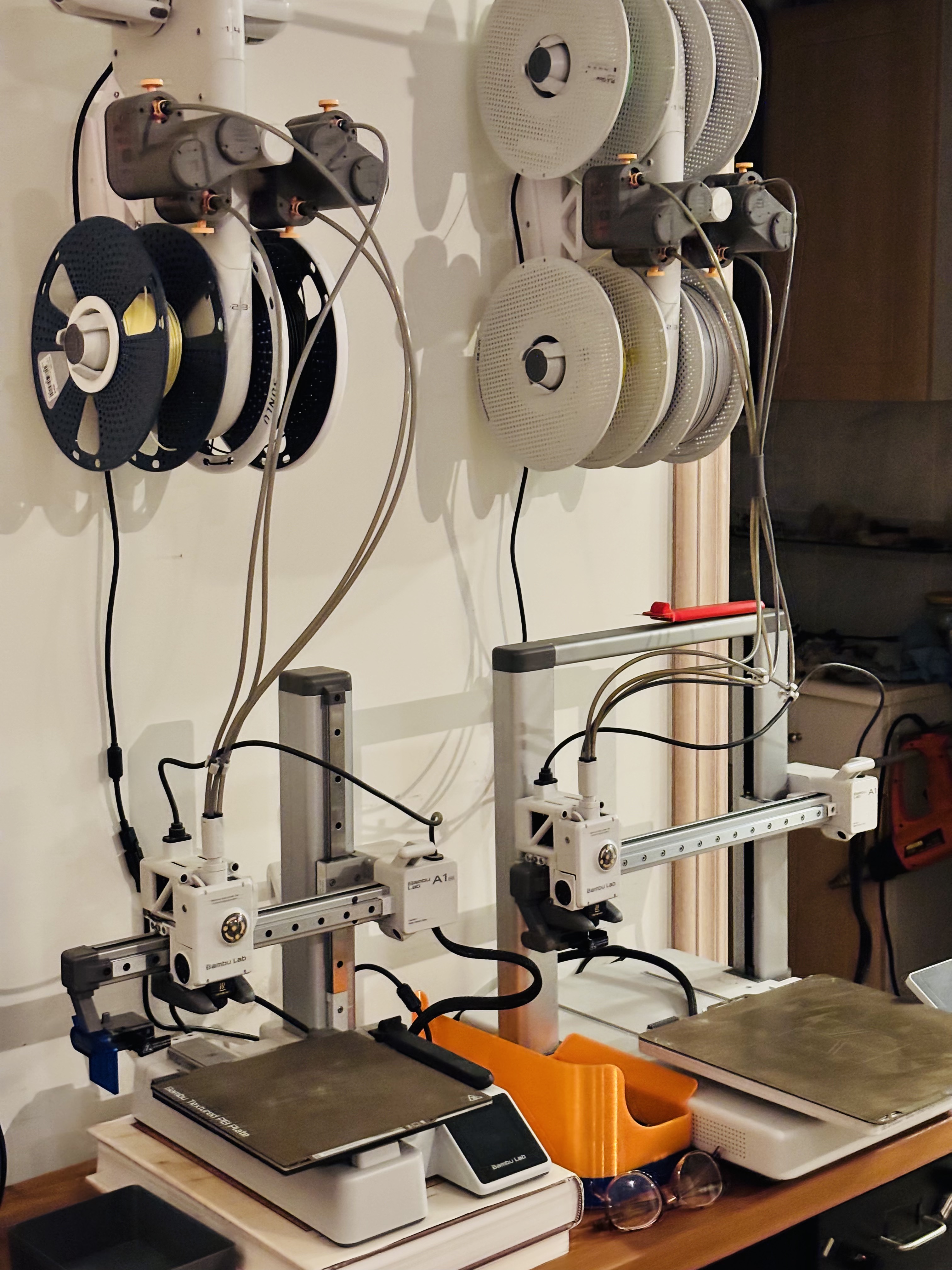

The Heart of the Studio: Printers, People, and Quiet Humming

Most days start and end in front of the machines. A Bambu Lab X1-Carbon handles demanding pieces and multi-colour work, while smaller printers pick up specialized jobs and prototypes. It’s less “factory line” and more “small orchestra”—each machine has a role, a sound, and a personality.

What Happens Before You See a Listing

- Concept sketch: ideas start as scribbles, notes, or a “what if we…?” moment.

- Digital model: the design is refined in 3D software until every curve behaves.

- Test prints: first attempts get pushed, bent, and examined up close.

- Final tuning: only when the print is repeatable and beautiful does it reach the shop.

Why a Small Print Farm Feels Different

- Hands-on control: settings are tuned by a person, not a distant factory profile.

- Immediate feedback: if a detail could be better, the change happens the same day.

- Real-life testing: pieces live on actual shelves and desks before they live on yours.

- Limited runs: small batches keep quality consistent and designs fresh.

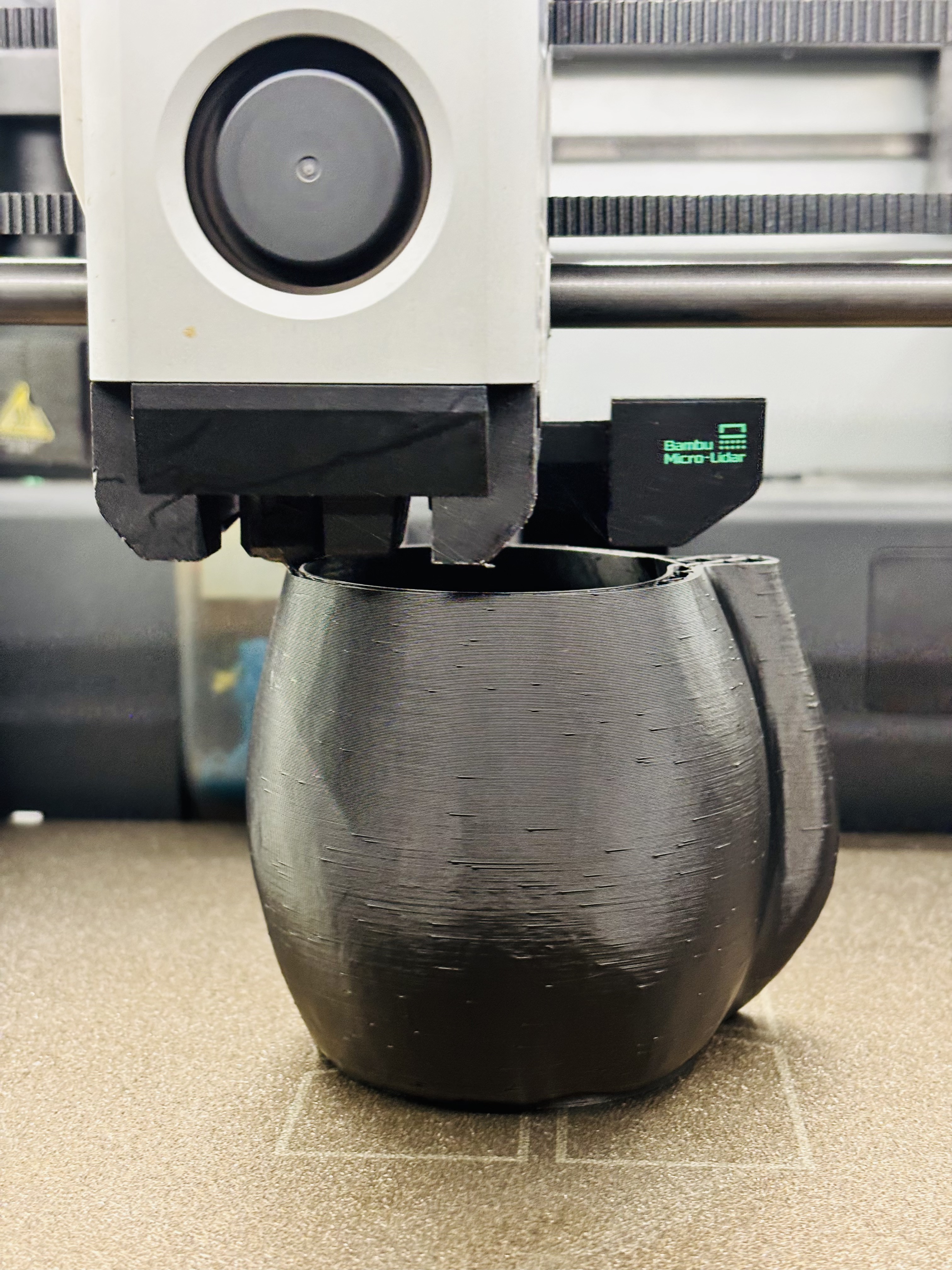

Layer by Layer: Watching Ideas Become Real

There is a quiet magic in watching a print grow. The nozzle moves in confident paths; the object appears slice by slice; the studio dog occasionally checks for falling scraps. It’s slow, patient work—exactly the opposite of one-click shopping—and that’s what makes it satisfying.

- First layers: dialing in adhesion so a print stays put without being impossible to remove.

- Mid-print checks: monitoring supports, bridges, and fine details as the form appears.

- Final passes: slowing down surfaces that need to be especially clean and visible.

- Post-processing: removing wisps, checking fit, and making sure it feels good in the hand.

Color Walls and Filament Forests

Behind every finished piece there’s a wall (and a ladder, and a shelf) full of filament. Pearlescent tones for special decor, sturdy basics for everyday pieces, transparent shades for light boxes—it all lives within arm’s reach.

- Curated palette: not every color makes the cut; only those that photograph well and feel good in real rooms.

- Material choices: PLA for decor, tougher blends for parts that need extra durability.

- Real-world testing: new colors are printed, handled, and lit before they ever appear in a product photo.

The Studio Dog, the Bike, and the Human Behind It All

This studio isn’t a closed lab; it’s where real life passes through every day. The dog claims the best sunny spot. The bike trainer waits for quick rides between print checks. Family walks past the glass, and late evenings end with one last look at the build plates before the lights go off.

That mix of work and life is part of what makes each piece feel personal. You’re not just buying from “a shop”; you’re inviting a small, slightly chaotic, very real creative space into your home.

From Studio to Your Home: Bringing a Little of This World to Yours

Every order that leaves the studio starts here—with a design session, a print queue, a wagging tail under the desk, and a human doing careful checks before anything gets boxed.

Personalised 3D Gifts

Nameplates, decor, keepsakes—pieces designed to feel like they belong to one person, not everyone.

Browse Custom PiecesSeasonal Collections

Christmas, Camino de Santiago, and more: curated designs that ship straight from this studio to your shelf.

See What’s in SeasonWant Something Just for You?

Have an idea in mind? Custom requests start with a message and a sketch—we’ll build the rest together.

Request a Custom DesignCaring for 3D Printed Pieces

Once a piece leaves the studio, the goal is simple: it should last, and it should keep looking good.

- Dust with a soft, dry cloth; for stubborn spots, use a barely damp microfiber.

- Keep decor away from strong direct heat sources or prolonged, harsh sunlight.

- Store seasonal items in a padded box so thin details and edges stay protected.

- If a part ever arrives damaged, reach out—small studio means real replies, not ticket numbers.

Questions People Often Ask

Do you really print everything yourself?

Yes. Every piece in the shop is designed, printed, and checked in this studio. No outsourcing, no giant factory runs.

Can I request a different color or size?

Often, yes. Many designs can be resized or re-colored within safe printing limits. If you have something specific in mind, send a message and we’ll see what’s possible.

Do you ship internationally?

Orders regularly travel across Europe and beyond. Shipping options and delivery times are shown at checkout, and pieces are packed with their whole journey in mind.

Why This Little Studio Matters

In a world of mass-produced everything, small studios like this one are where objects still carry a story. Every print that leaves the farm has passed through real hands, real tools, and a space where life is happening all around it.

If you’ve ever wondered what’s on the other side of the “add to cart” button at 3D2order, now you’ve seen it: a dog on a mat, a bike by the door, printers humming, and a maker who still gets excited every time a new idea turns into something real.

Take a Little Piece of the Studio Home

You don’t have to own a print farm to enjoy what comes out of one. Whether it’s a personalised gift, a Camino keepsake, or a seasonal decoration, each piece carries a small part of this studio’s everyday magic.